Pre-Bid Design Consulting

In our experience we have found meeting with our programmers for design consultation has led to great cost savings for our customers as manufacturing processes are streamlined and become much more efficient. Our programmers will meet with your engineers before bidding even starts without any contractual obligation.

In the past we have met with multiple companies to assist them in their design process. With over 50 years of prototype design experience, our programmers have the skill and knowledge to help ensure your project is a success both quality and cost wise!

To set up a consultation or to learn more please contact us at lyndsay@braswellprecision.com or shawna@braswellprecision.com or call 410.761.3366.

Process Excellence

We believe having excellent processes is critical to a job's success. We are continuously evaluating and improving on our processes, and implementing new technologies where we see fit. Improved processes increases our efficiency and problem prevention allowing us to better serve our customers. Part of having strong processes in tact is operating as a team. By applying skills and tools that are fundamental to effective team work: effective communication, execution of team decisions, and ongoing development of the team as a unit we are able to accurately access and carry out our operations.

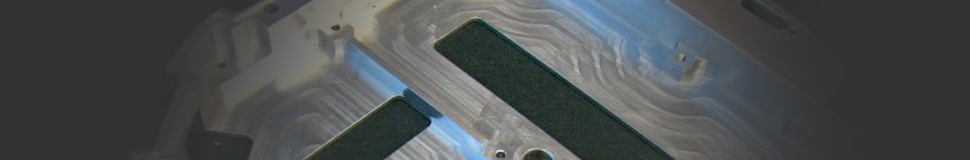

The process starts in our programming department. With over 50 yrs of experience in programming a host of different parts, our talented programmers can offer design assistance to your company's engineers to create a more efficient and economical part.

We use the latest CAD/CAM software to ensure parts are made accurately and successfully. Through computer translation conventions (ie.Step, IGES, DXF, DWG), our system connects directly to your engineering CAD system providing key information.

Quality Download

BPI deals with profound industries and we recognize how essential it is to deliver accurate parts to our customers. Excellence is achieved through our systematic concentration and practice of prevention over detection.

BPI's formal Quality Assurance Program guarantees consistent unsurpassed quality which includes an aggressive inspection process of first operation inspection, in-process inspection, pre and post plating inspection if applicable, and a final inspection. Our equipment is kept in working condition and is calibrated and traceable to the National Bureau of Standards. We utilize 3 CMMs (coordinating measuring machines), 2 optical comparators, and a wide variety of measuring instruments.

Our program satisfies all military requirements of ISO-9001:2015. Mandatory periodic reviews are part of BPI's Process Improvement Program, assuring continuous compliance with the industry's most up-to-date quality criteria.

In every aspect of our business we strive to follow Six Sigma business principles including marketing, finance and product development to business services, engineering, and human resources to inevitably produce a quality product with reduction of unnecessary waste. We are continuously working to improve our quality to deliver more value to our customer.

We can accommodate for any quality system and we allow first article and source inspection.

Scheduling & Delivery

We work with our customer to set a delivery date and we will work aggressively to satisfy it. Our manufacturing capacity allows us the benefit of offering scheduling flexibility and just-in-time delivery.

We use an effective scheduling system that is easily accessible in the event the customer wants to change the delivery date or make adjustments. We make every effort to accommodate changes.

Our network of suppliers and subcontractors we have developed respect and understand our dedication to meet our delivery dates to further ensure we fulfill our requirements.